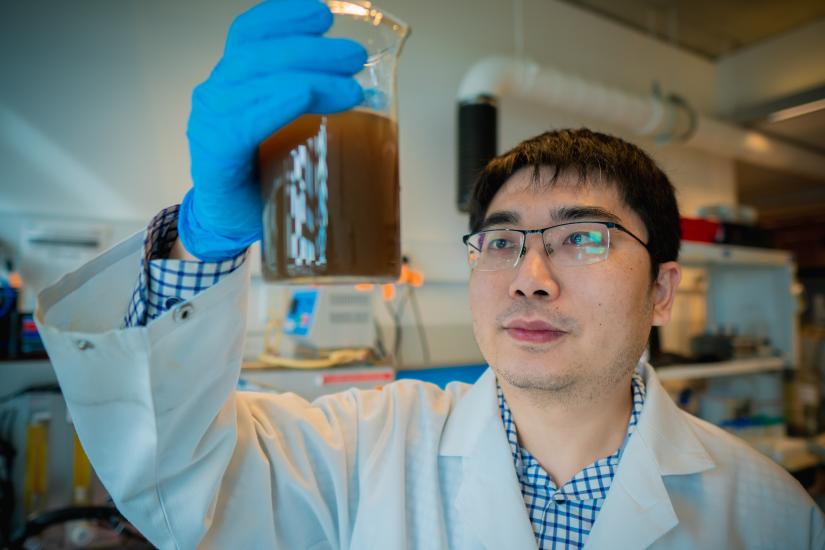

Some treatment plants already produce what’s known as biogas but existing processes recover just 5 to 10 per cent of the energy stored in sewage sludge, says Dr Qilin Wang, an environmental engineer with the Centre for Technology in Water and Wastewater Treatment at the University of Technology Sydney (UTS).

His pioneering technology, still in development, would maximise energy recovery by recruiting an otherwise unloved by-product of the wastewater treatment process – free ammonia.

Laboratory experiments suggest this ‘green’ technology could improve energy recovery from sewage sludge by four to six times. It’s also easy to implement, with no need for special equipment or inputs such as chemicals or external energy.

“My goal is to try to transform the energy-consuming and high emissions sewage treatment process into a zero energy – or, even better, energy producing – low-emissions process,” Dr Wang says.

In an added bonus, recent experiments suggest this free-ammonia technology could also reduce the presence of antibiotic resistant genes in the sludge, and therefore in the environment.

What is sludge?

Basically, sewage sludge is the solid waste produced during the sewage treatment process.

Sludge consists of organic and inorganic matter – including carbon, nitrogen and phosphorous but also things like chemicals and pathogens – and has to be treated very carefully prior to disposal or further use. In Australia, treated sludge is frequently sent off for use on agricultural land.

In the treatment plant, the sludge goes through an anaerobic digestion process. It’s this process that produces methane-rich biogas as the organic matter breaks down.

Dr Wang has been working to increase the amount of organic matter available to the microorganisms involved in anaerobic digestion so they have more ‘food’ to consume, in turn producing more biogas.

The challenges

“The first challenge is that some of the sewage sludge cannot be used as a food for the microorganisms – some of the sludge cannot be biodegraded,” Dr Wang explains.

The second challenge is that there’s competition for the organic matter from another process involved in the nitrogen removal during sewage treatment.

“One of the primary purposes of a sewage treatment plant is to remove nutrients – for instance, to remove nitrogen, to remove phosphorus,” says Dr Wang. “But the nitrogen removal process also needs organics.”

This is where his new technology comes in, using free ammonia to transform some of the non-biodegradable organics into biodegradable organics, meaning there’s more to go around. In addition, the free-ammonia technology changes the nitrogen removal process so it needs much less organic matter than the current process, freeing up organics for biogas production.

It’s a simple process. Sewage sludge is added into a simple mixing tank, to be joined by free ammonia. “Then we just mix them for around for a day or so,” Dr Wang says.

In effect, the technology turns free ammonia into a ‘good guy’ – at least for a while – making it an input rather than just a waste product that must be removed.

(Free ammonia includes nitrogen. If it’s not removed it can cause eutrophication in the water bodies where it’s discharged. This means the environment becomes overly enriched with nutrients, causing effects such as algal blooms or fish deaths from lack of oxygen.)

The technology can protect the environment and potentially protect human health too.

— Dr Qilin Wang

Antibiotic resistance

In an exciting development, recent work suggests the free-ammonia technology could also reduce the presence of antibiotic resistant genes in sewage sludge.

“I wanted to see whether there were any extra benefits we could obtain,” Dr Wang says. “So I tested how the technology would affect antibiotic resistant genes. I found that, after using the technology, the presence of antibiotic resistance genes decreased in the sewage sludge.

“With sewage sludge going into the environment or for agricultural use, that means fewer antibiotic resistant genes will be discharged into the environment and agriculture. So the technology can protect the environment and potentially protect human health too.”

The World Health Organisation regards antimicrobial resistance as an increasingly serious threat to global health.

With sewage treatment accounting for 10 to 25 per cent of councils’ energy costs, there are potential savings for municipalities and their ratepayers as well.

An international patent is being sought for Dr Wang’s free-ammonia technology and he has won a number of awards for his work. He was named among Australia’s Most Innovative Engineers 2020 for his work towards zero-energy wastewater treatment, with the judging panel saying the “closed system nature of this innovation is particularly powerful”.

“Generating energy from wastewater treatment rather than consuming it will change the dynamics for local government areas that are responsible for water supply,” the panel said.

Dr Wang’s research is being funded with the help of a three-year Australian Research Council Discovery Grant, a four-year Australian Research Council Future Fellowship, and industry support from groups such as Water Research Australia.

Research team

-

Senior Lecturer, School of Civil and Environmental Engineering

Funded by

- Australian Research Council Discovery Grant ($262,538, 2020–2023)